● Introduction

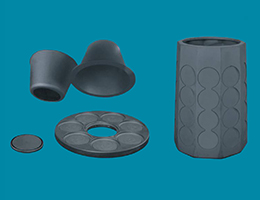

At present, the most popular technology of semiconductor etching is dry plasma etching, which used as a micro process by plasmas. Dry etching process is a combination of chemical reaction and physical bombardment. This technology has been widely used in microelectronics manufacturing. It has good anisotropic and process controllability compared with the traditional wet etching technology. Now it is extended to other areas,such as LED and so on. Solid silicon carbide mainly used as focusing rings, boundary loops and showerheads.

● Characteristics

1.High strength(Moh’s hardness of 9.5, the next of diamond)

2.Good corrosion resistance of acid, alkali and organic solvent.

3.Semiconductor

● Parameter

Performance comparison of these materials,quartz, silicon, RB-silicon carbide, CVD-silicon carbide

| property | quartz | Silicon |

RB Silicon |

CVD Silicon carbide |

| Density | 2.2 | 2.33 | 3.1 | 3.21 |

| Bending strength(MPa) | 49 | ~300 | 350 | 590 |

| Modulus of elasticity(MPa*104) | 7.8 | - | 41 | 45 |

| Toughness(MN/m3/2) | - | - | 3.5 | - |

| C.T.E(*10-6/K) | 0.5 | 2.3 | 4.3 | 4 |

| Thermal conductivity(W/m.K) | 1.3 | 150 | 67 | 250 |

| resistivity(Ωcm) | 1013 | 0.02,1~5 外 | 0.1 | 0.01~20000 |

| crystal structure | Irregular | cubical | hexagonal | cubical(β ) |

| lattice constant (Å) | - | a = 5.4307 | a = 3.0, c= 10 ~37 | a = 4.3596 |

| energy gap (eV) | - | 1.11 | 2.86 | 2.20 |

| dielectric constant | - | 11.7 | 6.52 | 6.52 |

| decomposition temperature(℃) | - | - | 1,500 | 2,000↑ |

| eutectic temperature(℃) | 1,700 | 1,427 | - | - |