● Introduction

MOCVD(Metal-organic

Chemical Vapor Deposition)is a special process to grow semiconductor

thin films on the matrix. It was developed on the basis of vapor phase

epitaxial (VPE) growth, and has become a new technology in VPE. The

source materials of crystals grown by MOCVD are metal organic compound

and hydride. The metal generally from group Ⅱ or Ⅲ when the later is

made by the elements of group V、Ⅵ. The vapor phase epitaxial growth on

substrates follows the method of thermal decomposition reaction, and

gains semiconductive chemical compounds of the group Ⅲ-V,Ⅱ-Ⅵ, and their

thin layer crystal materials of multiple solid solution.

The resistance wire heater mainly used in the equipment of Thomas

(Have been acquired by aixtron). The heating wire is generally made of

tungsten, and the reflective liner is made of PBN. Resistance heating

takes radiation heat transfer as the mainly principal. To achieve a

completely uniform temperature distribution, it optimizes structure of

all parts by the way of heating in multi-area.

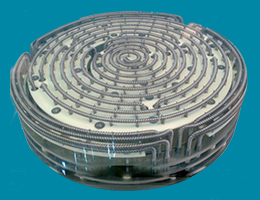

The resistor disc heater is mainly used in Veeco. Heaters can heat directly and have high heating efficiency.

● Parameter

|

Equipment supplier |

type |

heater |

|||

|

Thomas Swan |

19x2” |

31x2” |

54x2” |

69x2” |

Zone A/B/C |

|

Veeco |

21 x2” |

45 x2” |

Zone I/M/O |

||

● Application:

It is used for heating the basal disc of MOCVD equipments.